Through my internship at Seatrec, I gained hands-on exposure to electronics design under the guidance of Robin, who introduced me to the fundamentals of PCB layout, schematic design, and design-for-manufacturing considerations. Applying what I learned, I began designing my own custom printed circuit boards using KiCad, allowing me to move from mechanical-only projects toward fully integrated electro-mechanical systems.

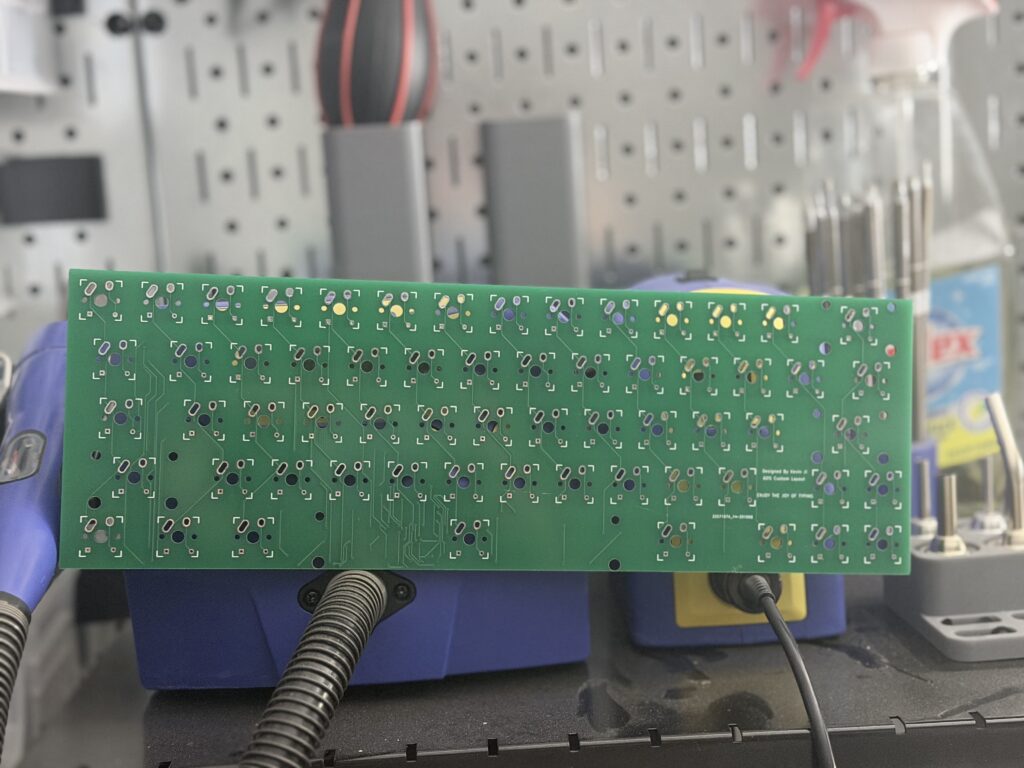

One of my first independent PCB projects was a custom mechanical keyboard PCB, where I designed the schematic, switch matrix, and board layout from scratch. This project helped me understand signal routing, component placement, tolerances, and the practical challenges of turning a digital design into a manufacturable board. Seeing the PCB function as intended reinforced the value of careful planning and iterative design.

In parallel, I worked on restoring a vintage Polaroid camera, which involved reverse-engineering parts of its electrical system and exploring ways to modernize its power delivery while preserving its original mechanical character. I also designed a battery management PCB for my drone system using 18650 Li-ion cells, aiming to create a modular, higher-capacity alternative to standard packs. Although this design ultimately did not make it into the final build—due to weight constraints, form-factor limitations, and the increased complexity compared to Li-Po batteries—the process was a valuable lesson in real-world engineering trade-offs. In the end, switching to a Li-Po solution proved more practical for high-current, weight-sensitive flight applications.

These projects helped me understand how electrical design choices affect system performance, safety, and integration. More importantly, they taught me that engineering progress often comes from iterations that do not work as planned, and that knowing when to pivot is just as important as knowing how to design.